PRODUCT

PRODUCT  HOME > Product > Horizontal Milling Machine

HOME > Product > Horizontal Milling Machine

PRODUCT DETAIL

PRODUCT DETAIL

MACHINE FEATURES

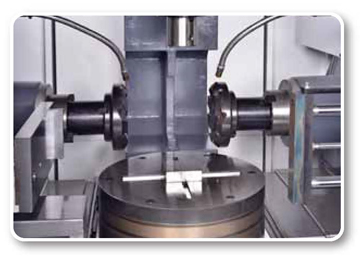

。Using powerful gear type cutting spindle.

。One-piece or multi-piece set once processing is completed on all sides.

。XYZ axis slide using a high rigidity box way structure, accuracy and stability, resistance to heavy cutting.

。XY(left right spindle), Z(longitudinal axis), A(work piece rotational axis), B(weight side axis) are controlled using a servo motor.

。Gear type spindle has high, medium and low speed range, with another inverter.

。High-pressure hydraulic cylinder vertical work piece clamping.

。Work piece auto measuring system and automatic positioning system.

MACHINE SPECIFICATION

|

MODEL |

LK-H500CNC |

|

Cutting Rang |

|

|

Cutting width |

30-500 mm |

|

Cutting Thickness |

200 mm |

|

Servo-controlled axes |

5-axis |

|

Gear Spindle |

|

|

Spindle speed |

(L)200rpm、(M)400rpm、(H)860rpm |

|

Spindle motor |

7 1/2 HP |

|

Inverter |

10 HP |

|

Spindle taper |

NT-50 |

|

XYZ Axis Travel |

|

|

X axis travel |

360 mm |

|

Y axis travel |

360 mm |

|

Z axis travel |

760 mm |

|

XYZ Axis Motor |

|

|

X axis motor |

1kw |

|

Y axis motor |

1kw |

|

Z axis motor |

2kw |

|

XY axis speed |

20m/min |

|

Z axis speed |

10m/min |

|

Rotary table allow heavy load |

350kg |

|

Hydraulic tank |

80L |

|

N.W. |

7.3 Ton |

|

Machine dimension (WxLxH) |

3300mm x 2890mm x 2200mm |

※Cutting capacity can be modified according to customer request.

STANDARD ACCESSORIES

|

1. SYNTEC Controller |

8. Inverter |

|

2. Automatic measuring system |

9. Optical scale |

|

3. Automatic positioning system |

10. Pressure lock tool |

|

4. Automatic lubrication system |

11. Work lights |

|

5. Automatic spray system |

12. Chip bucket |

|

6. Automatic screw type chip conveyor |

13. Toolbox & Pad |

|

7. Hydraulic block system |

|